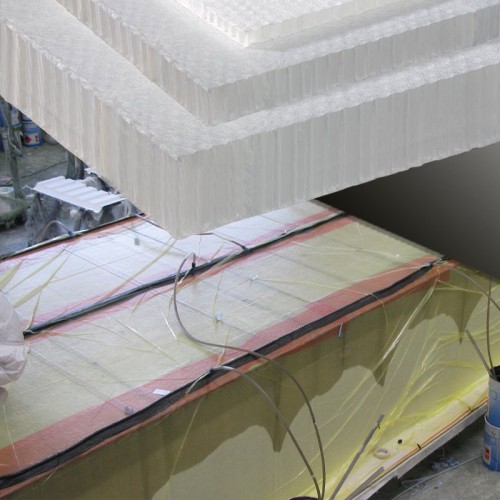

Nidaplast sheets made up of extruded polypropylene honeycombs are coated on both sides with a plastic film and a non-woven fabric, facilitating laminating, gluing or infusion techniques.

Why choose the infusion with nidaplast polypropylene honeycombs?

- Meet environmental standards and improve working conditions (reduction of VOC emissions)

- Improve the quality, by a good surface condition, a low porosity and a high fiber rate

- Reduce the cost of raw materials: the quantities of raw materials are better evaluated

- Reduce labor costs

- Reduce cost prices

The advantages of nidaplast honeycomb polypropylene panels are numerous.

Rot-proof, they are recommended for boating applications, but their compressive and impact resistance allows them to be used in many applications. In buildings, their thermal and sound comfort makes them suitable materials for both interior decorative panels and exterior facings.

This process is particularly suitable for industrialization and the manufacture of large-size composite parts.

Polypropylene honeycomb panels for infusion

The nidaplast 8RI is a polypropylene honeycomb core covered with a polyester non-woven fabric and a polypropylene film specially reinforced to resist the pressure of the resin on the core, due to the implementation in infusion ( infusion supply, infusion consumables, vacuum infusion)

These materials thus prevent the resin from filling the cells.

We sell exclusively to professionals from an order threshold. If you are a professional, contact us to study your requests.